Ericsson’s Texas 5G Smart Factory: A Model for the Future of Manufacturing

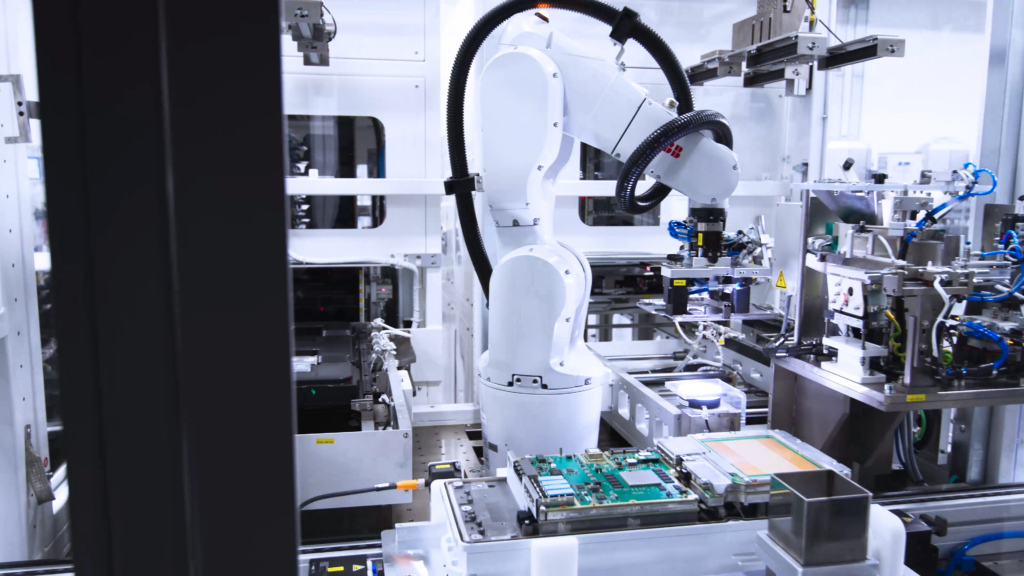

The global telecommunications giant, Ericsson, has developed a state-of-the-art, highly automated smart factory in Lewisville, TX, using 5G to enable agile operations and flexible production. The use of 5G allows for real-time data collection and analysis, provides a high-speed, low-latency connection that is essential for the operation of automated machines and can be used to connect the factory to the cloud, which allows for remote monitoring and control. As a result of these innovations, Ericsson’s Texas 5G Smart Factory has been recognized as a global leader in the Fourth Industrial Revolution. The factory has been awarded the World Economic Forum’s “Global Lighthouse” designation, given to facilities at the forefront of 4IR adoption.

Here are some of the key benefits of Ericsson’s Texas 5G Smart Factory:

- Increased efficiency: The factory is able to produce more radios with optimized processes and increased production.

- Improved quality: The use of automation and data analytics has led to a decrease in defects.

- Increased flexibility: The factory can be easily reconfigured to produce new products.

- Improved sustainability: The factory is powered by 100% renewable energy.

At a Glance

Enhanced Efficiency

Ericsson’s 5G Smart Factory produces more radios with optimized processes and increased production

Superior Quality

Automation and data analytics reduce defects.

Sustainable Operations

Ericsson’s 5G Smart Factory is powered by 100% renewable energy.